In recent years, the manufacturing industry has seen significant shifts. Companies constantly seek methods to save expenses and boost efficiency. Now, the efficiency is key in manufacturing. According to the report, global supply chain disruptions caused significant delays for 75% of manufacturers. This highlights the need for streamlined processes. One major development is the use of cloud solutions to streamline supply chain and production processes. 40% of supply chain professionals surveyed had integrated advanced technology like cloud computing and storage into firm operations. Inventory and network optimisation solutions are most likely to be adopted by supply chain organisations in five years.

Therefore, the manufacturing sector needs a robust solution for supply chain automation like Boomi iPaaS for integrating the various systems and technologies. Boomi helps connect different systems and processes, making operations smoother and more efficient. This blog will discuss how Boomi is transforming manufacturing, with a particular focus on its benefits in retail. We will look at how it integrates e-commerce platforms, inventory management systems, and customer relationship management (CRM) tools.

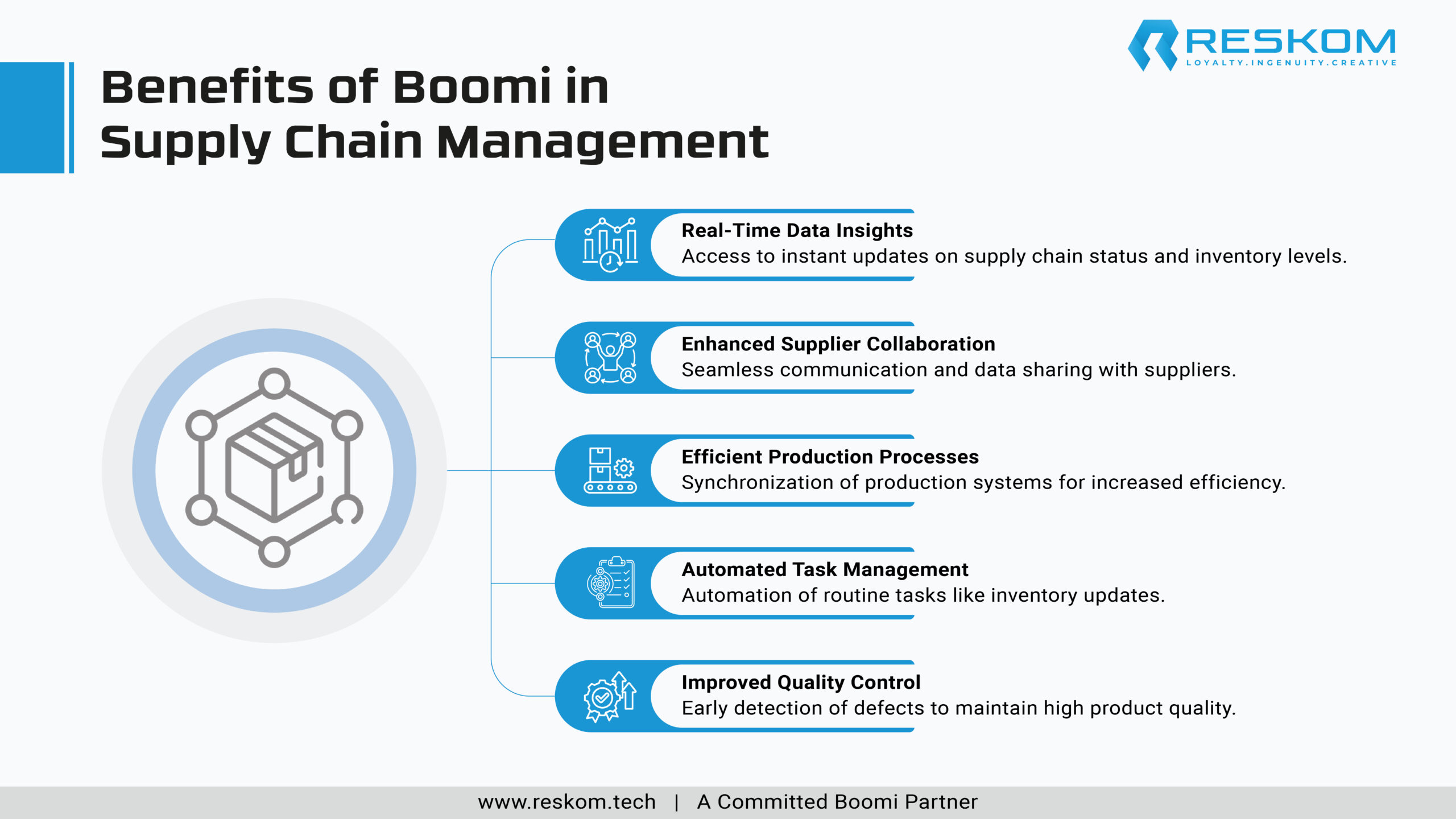

How Boomi Can Help Streamline Supply Chain Management

Supply chain management is a complex process involving many steps and systems. Boomi helps simplify these processes by providing a platform that connects various systems seamlessly. This integration is crucial for ensuring that information flows smoothly between different parts of the supply chain.

Real-Time Data for Better Decision-Making

One of the key benefits of using Boomi in supply chain management is access to real-time data. This data allows manufacturers to make informed decisions quickly. For example, if there’s a delay in receiving raw materials, the system can immediately notify the relevant departments. This early warning helps prevent production slowdowns and ensures that deadlines are met.

Improved Supplier Collaboration

Another significant advantage is improved collaboration with suppliers. Boomi enables manufacturers to connect their systems with those of their suppliers. This connection means that both parties can share information and updates in real time. Better communication improves coordination and reduces misunderstandings.

Streamlining Production Processes

Boomi also plays a critical role in streamlining production processes. By integrating various production systems, Boomi ensures that every part of the production line is synchronized. This synchronization leads to increased efficiency and reduced waste.

Automation of Routine Tasks

Boomi can automate many routine tasks involved in production. For instance, it can automatically update inventory levels as products are manufactured and shipped. This automation reduces the need for manual input, which can be time-consuming and prone to errors.

Enhanced Quality Control

Quality control is another area where Boomi shines. By integrating quality control systems with the production line, Boomi ensures that any defects are detected early. This early detection means that corrective actions can be taken promptly, reducing the number of defective products that reach the market.

Enhancing Production Planning with Boomi

Production planning is another area where Boomi can make a big difference. Effective production planning ensures that manufacturing processes run smoothly and efficiently.

- Integrating Planning and Execution Systems

Many manufacturers use separate systems for planning and execution. This can lead to miscommunication and inefficiencies. Boomi integrates these systems, ensuring that plans are executed as intended. This integration reduces errors and increases efficiency. - Optimizing Inventory Management

Boomi also helps optimize inventory management. By connecting inventory data with production schedules, Boomi ensures that the right amount of materials is available when needed. This reduces both shortages and excess inventory, saving money and space.

Leveraging IoT Data with Boomi

The Internet of Things (IoT) is revolutionizing manufacturing by providing real-time data from machines and equipment. Boomi can help manufacturers make the most of this data.

Monitoring Equipment Performance

Boomi can integrate IoT data with other systems to monitor equipment performance. This allows manufacturers to identify and address issues before they cause downtime. For example, if a machine is operating below its optimal level, the system can alert the maintenance team to take corrective action.

Improving Product Quality

IoT data can also be used to improve product quality. By analyzing data from sensors, Boomi can identify trends and patterns that affect quality. Manufacturers can then adjust their processes to ensure consistent product quality.

Case Study: Boomi Integration Simplifies Supply Chain Logistics for Emmelibri

Emmelibri, the supply chain and logistics coordinator for Messaggerie Italiane, faced challenges in managing a complex network involving multivendor, distributed applications. Their existing SAP system could no longer handle the integration needs of their extensive book distribution network, which includes wholesalers, distributors, warehouses, and large-scale retailers. They required a solution that could ensure streamlined and accurate information exchange between ERP, logistics, warehouse management, and e-commerce systems.

Boomi provided Emmelibri with the flexibility and agility needed to integrate approximately fifty systems and more than 180 processes and data flows. This low-code cloud solution enabled Emmelibri to create simple, user-friendly data flows, minimizing business disruption and requiring minimal management oversight. The ease of use of the Boomi Enterprise Platform allowed Emmelibri staff to handle most integration tasks in-house, transforming their logistics operations into one of the most modern and automated supply chain logistics sites in Europe. The results after Boomi implementation were outstanding:

- Automated and scalable integration for all stakeholders in the supply chain.

- Minimized business disruption through continuous cloud updates.

- Simplified systems management with minimal oversight required.

- Enabled in-house management of most integration tasks.

Why Choose Boomi for Your Manufacturing Needs?

Boomi offers several advantages for manufacturers looking to streamline their operations.

- Easy Integration: Boomi is designed to integrate with various systems, making it easy to connect different parts of the manufacturing process. This ensures a seamless flow of data and better coordination.

- Scalability: As your business grows, Boomi can grow with you. It is scalable and can handle increased data and more complex processes without any issues.

- Cost-Effective: By reducing delays and improving efficiency, Boomi helps save money. The return on investment can be significant, making it a cost-effective solution for manufacturers.

Transforming Manufacturing with Boomi

The manufacturing industry faces many challenges, but Boomi offers solutions that can help overcome them. By integrating supply chain management, production planning, and IoT data, Boomi provides manufacturers with the tools they need to operate more efficiently. The benefits include better visibility, real-time data, optimized inventory management, and improved product quality. Companies like Emmelibri have already seen the positive impact of Boomi, and your business could be next.

If you are looking to revolutionize your manufacturing processes, consider partnering with RESKOM and leveraging the power of Boomi. Contact our seasoned experts to learn more about how Boomi can help streamline your supply chain and production processes.