The manufacturing sector is seeing significant changes with the advent of new technologies. According to a study by the International Data Corporation (IDC), global spending on the Internet of Things will surpass $1 trillion in 2026. This shows how manufacturers are increasingly investing in digital solutions to improve their operations. One of the key players in this digital transformation is Boomi, a platform that helps integrate various systems and automate processes.

The Need for Enhanced Supply Chain Efficiency

A well-oiled supply chain is the backbone of any successful manufacturing operation. However, inefficiencies in this area can lead to a domino effect of problems, including:

- Inventory shortages: Delays in receiving raw materials can stall production and lead to missed deadlines.

- Excess inventory: Overstocking not only ties up valuable capital but also increases storage costs and the risk of obsolescence.

- Delayed deliveries: Inconsistent communication and visibility can result in missed shipments and frustrated customers.

Role of Boomi in Manufacturing

Boomi serves as a platform for integrating many platforms, apps, and data sources. In manufacturing, this means bringing together disparate systems such as inventory management, procurement, production, and distribution. Boomi ensures that all these systems communicate seamlessly, providing a unified view of operations.

By using Boomi, manufacturers can:

- Integrate various software and systems

- Automate manual processes

- Improve data visibility and accuracy

- Enhance decision-making capabilities

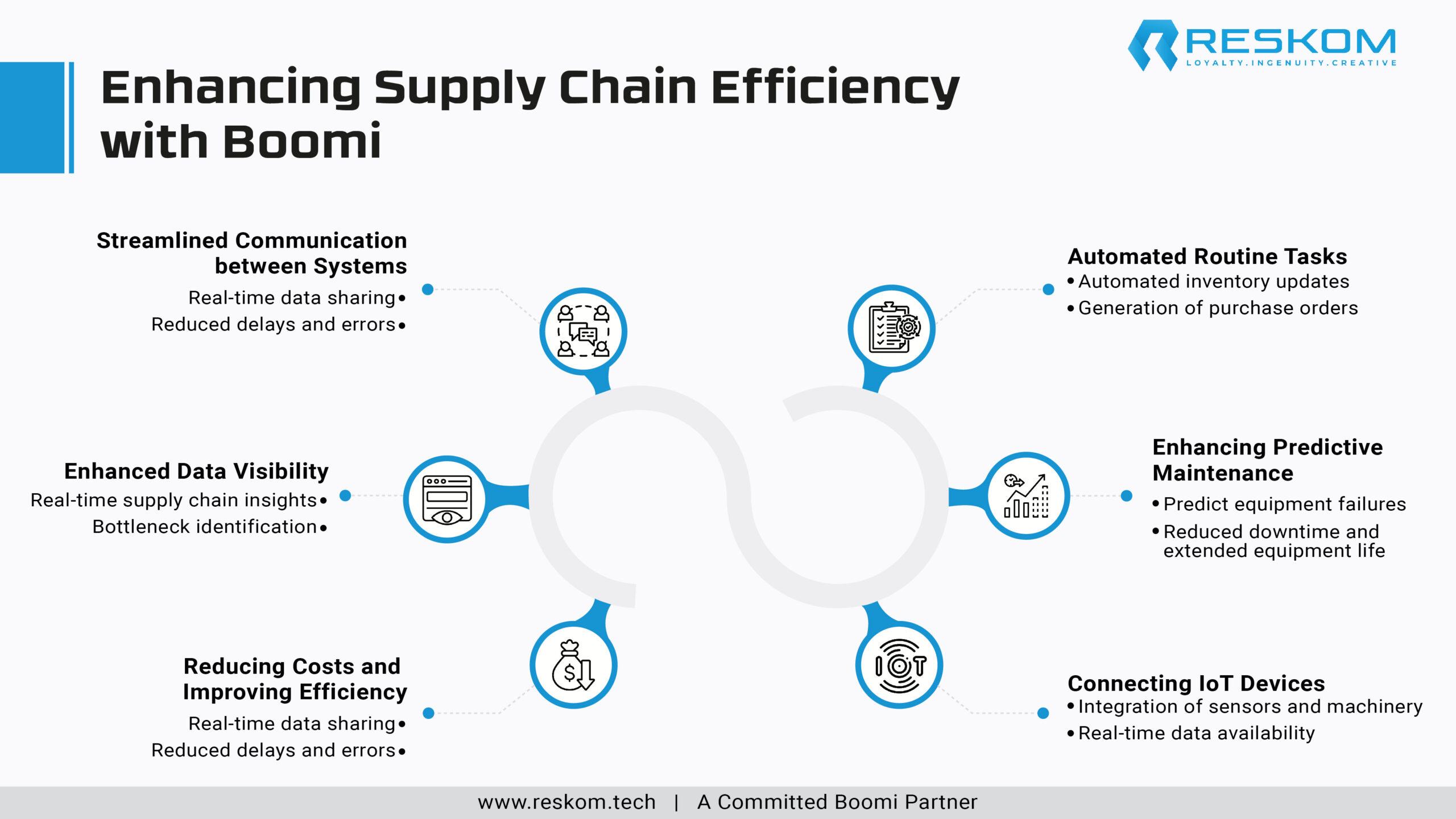

Improving Supply Chain Efficiency with Boomi

Supply chain efficiency is vital for any manufacturing business. Delays, errors, and lack of visibility can lead to significant losses. Boomi helps in several ways to improve supply chain efficiency.

Streamlining Communication between Systems

In a typical manufacturing setup, different departments use various software for their operations. For instance, the procurement team might use one system, while the production team uses another. Boomi integrates these systems, allowing them to share data in real-time. This reduces delays and errors caused by manual data entry and ensures that everyone has access to the latest information.

Automating Routine Tasks

Many tasks in the supply chain are repetitive and time-consuming. Boomi can automate these tasks, freeing up employees to focus on more strategic activities. For example, Boomi can automatically update inventory levels when new stock arrives or generate purchase orders when inventory falls below a certain threshold.

Enhancing Data Visibility

Making informed choices requires having a comprehensive understanding of the whole supply chain. Boomi provides real-time visibility into all aspects of the supply chain, from raw material procurement to finished product delivery. This allows managers to identify bottlenecks, track shipments, and manage resources more effectively.

Reducing Costs and Improving Efficiency

By integrating systems and automating processes, Boomi helps reduce operational costs. It eliminates the need for manual data entry, reduces errors, and improves the efficiency of various supply chain activities. This results in improved resource utilization and significant cost reductions.

The Rise of IoT in Manufacturing and its Benefits

The manufacturing sector is undergoing a change thanks to the Internet of Things. By integrating sensors and other connected devices into machines and equipment, manufacturers can gather real-time data on a wide range of parameters, including:

- Machine performance: Monitor equipment health, detect potential failures before they occur, and schedule preventive maintenance.

- Production line efficiency: Track production speed, identify bottlenecks and optimize processes to maximize output.

- Quality control: Real-time data allows for continuous quality monitoring, ensuring consistency and minimizing defects.

Integrating IoT with Boomi for Better Manufacturing Outcomes

The Internet of Things (IoT) is transforming the manufacturing industry by connecting machines, devices, and systems. IoT devices collect data from various sources, providing valuable insights into the production process. Boomi plays a crucial role in integrating these IoT devices with existing systems.

Connecting IoT Devices

Boomi can connect a wide range of IoT devices to existing manufacturing systems. This includes sensors, machinery, and other devices that collect data. By integrating these devices, Boomi ensures that the data collected is available in real-time and can be used for analysis and decision-making.

Analyzing IoT Data

The data gathered by Internet of Things (IoT) devices can shed light on a number of manufacturing-related topics. Boomi helps in analyzing this data by integrating it with analytics and business intelligence tools. This enables manufacturers to keep an eye on machinery performance, forecast maintenance requirements, and streamline workflows.

Enhancing Predictive Maintenance

Predictive maintenance is one of the significant benefits of IoT in manufacturing. By analyzing data from sensors and other IoT devices, Boomi can help predict when equipment is likely to fail. This allows manufacturers to perform maintenance before a breakdown occurs, reducing downtime and extending the lifespan of equipment.

Improving Product Quality

IoT devices can monitor various parameters during the production process, such as temperature, humidity, and pressure. Boomi integrates this data with quality control systems, helping manufacturers ensure that products meet the required standards. This leads to improved product quality and reduced wastage.

Use Cases of Boomi in Manufacturing

Many manufacturers are already leveraging Boomi to enhance their operations. Here are a few examples:

Inventory Management

A large manufacturing company can use Boomi to integrate its inventory management system with its procurement and production systems. This will allow for real-time updates on inventory levels, reducing stockouts and overstock situations. As a result, the company will be able to optimize its inventory levels and reduce carrying costs.

Order Processing

A manufacturer can automate its order processing system using Boomi. The platform integrates the company’s e-commerce platform with its ERP system, automating the entire order-to-cash process. This will reduce order processing time and improve customer satisfaction.

Equipment Monitoring

A company producing heavy machinery can integrate its IoT sensors with Boomi to monitor equipment performance. By analyzing data from the sensors, the company can predict equipment failures and perform maintenance proactively. This reduces downtime and improves the reliability of their equipment.

Supply Chain Coordination

A manufacturer can use Boomi to integrate its supply chain systems across different regions. This will provide a unified view of the entire supply chain, allowing the company to coordinate activities better and respond to disruptions quickly. This will improve supply chain resilience and reduce operational costs.

Summary

The manufacturing industry is undergoing a significant transformation with the adoption of digital technologies. Boomi is at the forefront of this change, helping manufacturers integrate systems, automate processes, and leverage IoT for better outcomes.

Boomi’s ability to streamline communication between systems, automate routine tasks, and enhance data visibility can significantly improve supply chain efficiency. At the same time, its integration capabilities with IoT devices can lead to better equipment monitoring, predictive maintenance, and improved product quality. Learn more on this topic or get a solution demo from the industry experts at RESKOM.